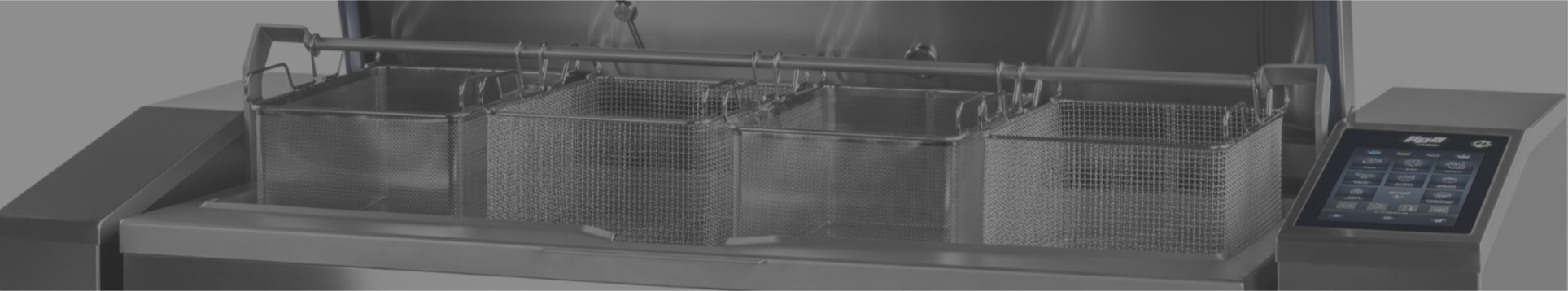

ELECTRIC MULTIFUNCTION DEVICE WITH AUTOMATIC BASKET LIFTING

Boiling, intensive and gentle cooking, frying, deep frying, braising, low temperature cooking, grill, searing, broiling, confit, sous-vide cooking (vacuum cooking at constant low temperatures). Temperature range 30-250 °C.

Automatic and manual food preparation mode

12″ color touch screen with intuitive operation

Complete control in the Czech language

Language mutations

Possibility to save own programs

Technological procedures

Memory for 800 programs in 12 steps

Showing the progress of the adjustments on the display

Accurate sensory temperature measurement

Indication of set and actual values

Display of error messages on the display

Technical and service information

On / Off button

Screen lock

© 2019 JIPA INTERNATIONAL | Tvorba webových stránek Grafické studio Designcrew